août 5, 2023

Quels sont les points bloquants à améliorer pour booster son référencement naturel ? Pour le savoir rapidement, il n’existe qu’un seul […]

mars 29, 2023

Que ce soit durant la période des rentrées où à n’importe quel moment de l’année, la recherche d’un appartement à […]

février 14, 2023

La prospection consiste à la recherche de prospects ou de nouveaux clients potentiels. Peu importe que vous soyez freelance, indépendant […]

novembre 29, 2022

On entend souvent parler de chanfreinage dans le domaine de l’usinage de pièces. Apprenez ce qu’est le chanfreinage dans le […]

novembre 25, 2022

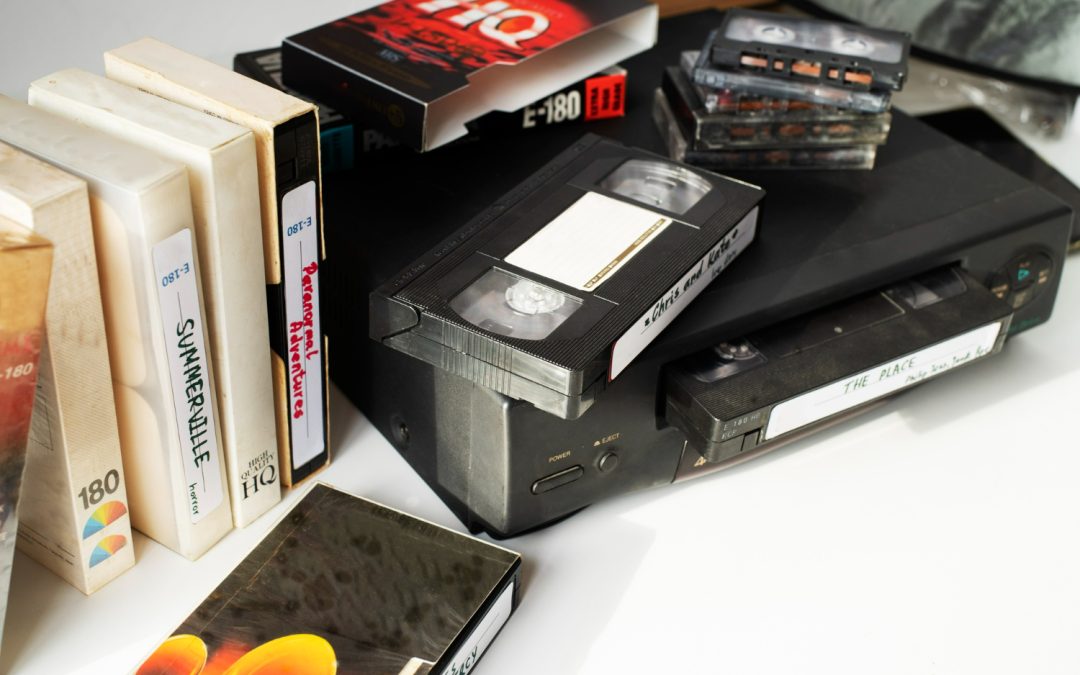

Le Wide-VHS ou le W-VHS fait partie des formats de vidéocassette permettant de réaliser des enregistrements analogiques. Introduit en 1994, […]

octobre 25, 2022

Le logiciel de gestion peut être d’une grande utilité pour une nouvelle entreprise. En effet, il aide à analyser et traiter […]

octobre 22, 2022

Vous souhaitez investir mais vous ne savez pas très bien comment vous y prendre pour mettre toutes les chances de […]

août 18, 2022

Vous préparez le projet d’acheter une nouvelle voiture et vous avez besoin d’un prêt. Afin de comparer les crédits en […]